Despite collaborative robots (catbots) being exactly they say on the tin there is still some confusion around the purpose, functionality and benefits to manufacturing. In this post, we aim to clearly state what they are, detail four different types and how they can be practically used to improve the manufacturing process.

Definition

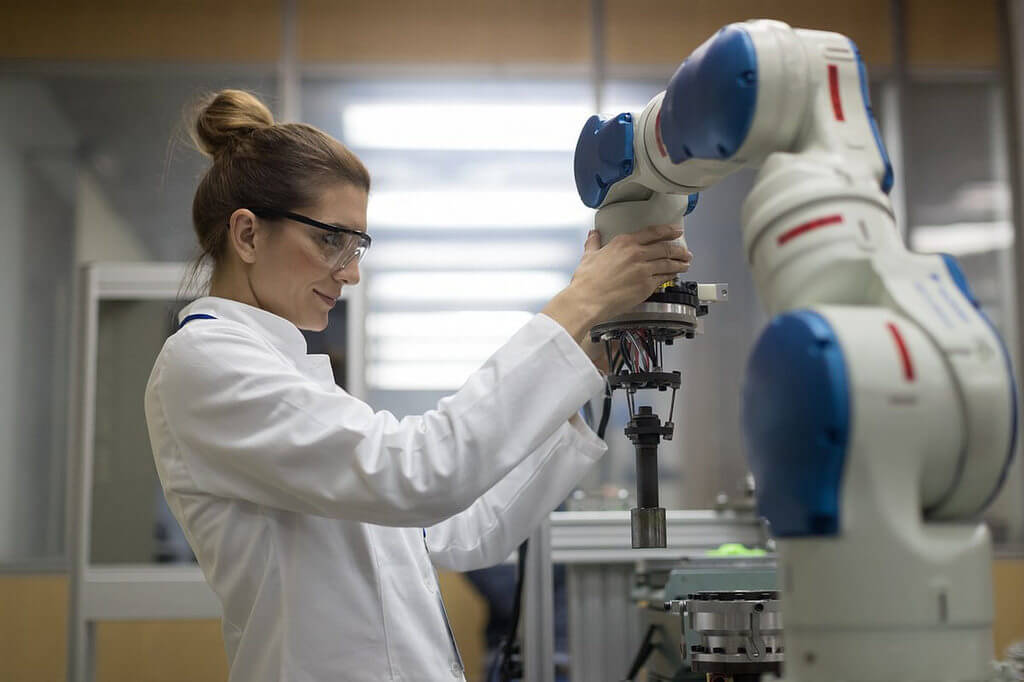

Robots are common in manufacturing but catbots are invented to aid the operator as opposed to working independently with automation. Collaborative robots are controlled by humans and are designed to enhance the productivity, safety or precision of the task.

Hand Guiding Catbots

This particular collaborative robot is usually provided as a device that delivers assistance to regular industrial robots by path teaching. The operator can use hand guiding to swiftly teach pick and place paths. It records the forces that are applied by the human so that the regular robots can then continue to replicate this same behaviour automatically.

Monitoring Catbots

Using vision systems or lasers this collaborative robot is able to adapt its movements based on the positioning of nearby humans. It is a sophisticated collaborative robot makes working with machinery considerably safer. It constantly monitors where people are around designated safety zones and will instantly use this data. The catbot will slow down as someone approaches and then stop completely when they get too close and return to full speed when the person is at a safe distance.

Power and Force Limiting Catbot

This catbot works alongside the worker as opposed to acting as a guiding device so in essence, it is what most people think of when they hear collaborative robot. Its function is to measure force and stop when it recognises an excessive force and can additionally dissipate these forces to reduce impact. To take such forces the robots themselves are rounder and have internal motors.

Force Limited Catbots

These collaborative robots use the pressure on their joints to measure forces. They learn what normal forces feel like and then they can subsequently recognise what an abnormal force feels like and stop accordingly. Instead of stopping completely it is also possible to program these robots to reverse positions. This safety feature means that if it comes into contact with a human worker it can instantly act to reduce chances of injury. Some have an additional ‘skin’ that provides a cushioning in case of contact but this skin is designed with extra senses to assist the catbot in reading its environment. This type of robot can also be used for hand guiding.

Like the monitoring catbots these are rounder in shape and their motors are built internally. They are designed in such a compact and efficient way that they are also referred to as a lightweight robot.

This type of collaborative robot is appealing because there are no additional safety features required which makes it a more economical investment. It also has simple programming features and can be integrated easily into any production lie and co-work with human employees, this again makes it a cost-effective collaborative robot to work with.

The Place for Collaborative Robots

Collaborative robots have earned their place as an integral part of the manufacturing industry, providing ever more efficient and safer environments to work in. Technology will keep evolving and as the manufacturing landscape continues to change, we are sure to see more innovation and progression from our friends, the catbots.