NEWS

NEWS

News and updates from the Innomech team

along with advice and industry commentary

NEWS

Unlocking smarter manufacturing: The role of data-driven automation

Data is transforming how manufacturers approach automation. Using real-time data to build bespoke automation systems that allow for better decision making, reduce downtime, and boost efficiency across the production line is what manufacturers across all sectors are...

How Bespoke Automation Enables More Sustainable Product and Component Manufacturing

While the spotlight often falls on the sustainability of the final product, what we sometimes fail to consider is the systems and components that we use to make the products and the vital role they play in building this sustainability. From improving material...

Custom Automation Solutions: Tailoring Technology to Your Needs

Custom automation proves that technology doesn’t come as a one-size-fits-all solution, and rightly so. We need technology to work for us, to meet our specific business requirements, and to allow businesses to adapt quickly and perform better. Automation technology is...

How to Protect Your Manufacturing Business From a Cyber-Attack

According to an IBM report into cyber security, manufacturing is the 2nd most hacked industry, second only to healthcare. This may come as a surprise; after all, it is easy to assume that the financial sector takes the biggest hit from cyber-attacks. While this might...

What you need to know about Industry 4.0

It doesn’t happen very often, but sometimes in human history we experience a revolution. We are currently entering the era of Industry 4.0 and although this particular revolution isn’t spurred on my civil unrest or an overthrow of the government, the manufacturing...

Medical Device Assembly: Case Studies

Read some of our case studies and articles for examples of some of the innovative projects we carry out with our clients and strategic partners. Innomech have experience in producing systems ranging from bench top measuring devices to fully automated medical device...

Innomech delivers for Aston Particle Technologies

Innomech has designed and developed a pilot-scale production system for Aston Particle Technologies (APT) that will help the company accelerate the commercialisation of its innovative dry particle coating technology for use within the pharmaceutical industry. APT is...

Innomech boosts Michell manufacturing efficiency

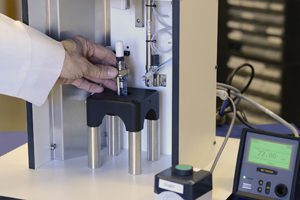

Innomech has designed and developed a new semi-automated workstation to help a major UK-based manufacturer - and another local Ely-based business - to improve the manufacturing efficiency for one of its leading ranges of high precision industrial sensors. The new...

Innomech strengthens software development team

Innomech has appointed Simon Carter as project controls engineer to specifically strengthen the company’s in-house resources for the design and development of automation control software. Simon brings over 20 years of automation industry experience into the...

General Engineering: Case Studies

Read some of our case studies for examples of some of the innovative projects we carry out with our clients and strategic partners. The diversity of experience that our engineering team has gathered over the years enables us to confidently select and combine...

Innomech develops high speed packaging for global supplier

Innomech has developed a new high speed automated product packaging system that will help SG Technologies – a global leader in the production of high performance magnetic components – to more than double the production capacity for one of its highest volume products....

Innomech and FCS Automation join forces for medical device manufacturers

Innomech and FCS Automation (FCS) have agreed to work together to offer medical device manufacturing companies a more integrated approach to robotics and automation. The new partnership will help companies looking to improve the efficiency, reliability, capacity or...

Innomech to attend Medtec 2016 in Stuttgart 12th – 14th April

Innomech will be sending a team to Medtec 2016 in Stuttgart between the 12th and 14th of April. The Innomech team will be based on Stand 5E37 in the Full Service contract manufacturing Zone, and will be available to offer an insight as to how they may help with any...

Innomech develops automated test system for Owen Mumford

Innomech has designed and developed a new fully automated test system to help Owen Mumford, a global leader in medical device design and manufacturing, to carry out more efficient batch testing as a final verification of quality for one of its leading auto-injector...

Innomech develops lens automated manufacturing for Rayner

Innomech has been appointed by Rayner Intraocular Lenses Limited (Rayner) to design and develop automated manufacturing equipment for the company’s new state-of-the-art production plant that is due to open in Worthing in July 2015. Innomech is developing several units...