Bottlenecks and production challenges in manufacturing are not uncommon.

It is a traditional industry with extensive processes and rigid production lines that often, due to factors outside our control, face bottlenecks that can negatively affect production output.

From challenges with overseas freight, ongoing economic uncertainty, labour shortages, COVID-19, and more, the manufacturing sector has faced and continues to face it all.

Of course, we know that some bottlenecks can come from inflexible planning and outdated processes. However, we also understand that most bottlenecks are outside of your control and, hence, completely unavoidable.

In these circumstances, there are things you can do to minimise the impact these factors have on your production lines.

This post uncovers practical solutions to overcoming common manufacturing bottlenecks and, as a result, increasing production capacity and efficiency as well as ensuring your business can meet growing demand.

Bottlenecks in Manufacturing

Not to continue scaremongering and forcing manufacturers toward panic planning, but some of the challenges the manufacturing sector is still facing, factors that continue to cause bottlenecks in processes, include:

Labour shortages – the manufacturing sector is currently facing an ageing workforce, highlighting a significant problem with skills shortages in the industry. There is also a recruitment problem within the sector, which is causing an increase in labour shortages when demand for production is high.

Inefficient production lines – production downtime delays production and disrupts operations, making it a costly problem for businesses. Production downtime can be the result of faulty machinery, old or tired equipment, poorly designed and inefficient processes, production capacity unable to meet demand effectively, and more.

Supply chain disruptions – politics, economic shifts, material shortages, not having the right materials in the right place at the right time, problems with transport links, and more can all lead to a bottleneck in manufacturing.

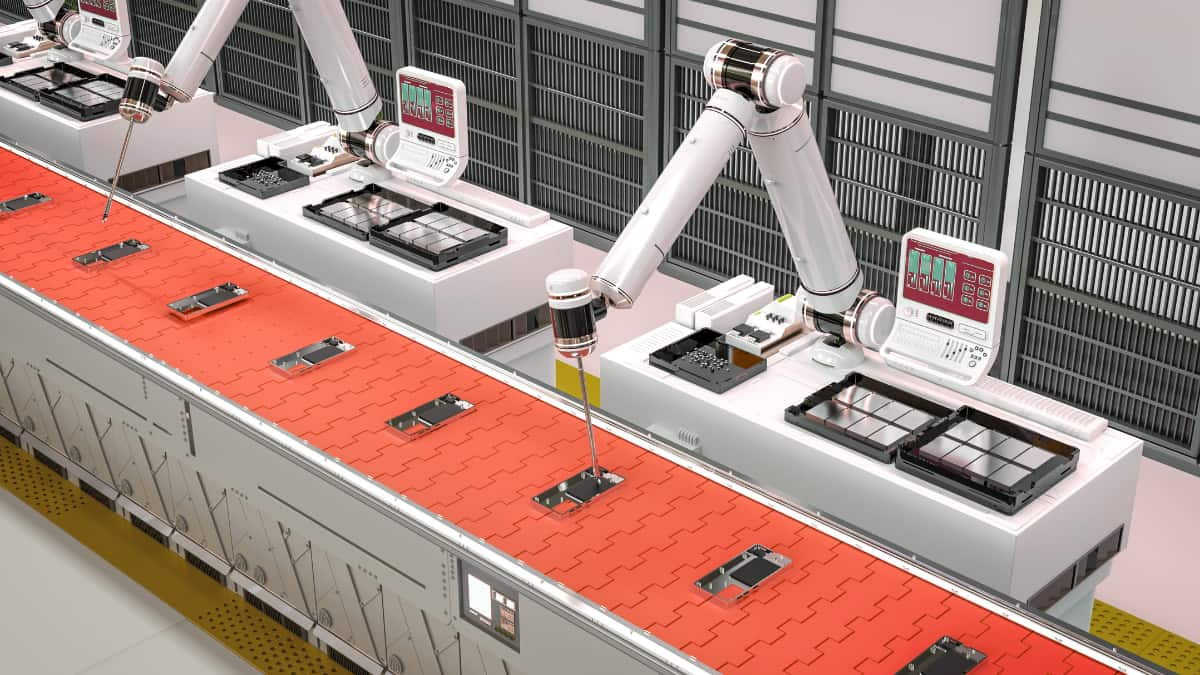

No automation – manual processes holding up production lines, poor/outdated inventory management systems, and no real-time data to help with forecasting, are all holding up advances in manufacturing and putting strain on current processes.

How can automation help you scale and overcome bottlenecks

Automation helps to eliminate manual labour. By automating the right processes, you can remove those labour-intensive, manual tasks from your team, allowing you to redeploy employees to other business areas and providing an opportunity for you to grow and scale.

By automating the time-consuming tasks, you can reduce the time required to carry out the processes, hence speeding up production and increasing manufacturing capacity and capability.

Moving employees away from monotonous tasks also allows you to upskill workers in other areas, creating more fulfilling job opportunities and helping tackle the labour shortage and recruitment challenge head-on.

The right automation tools also come with predictive maintenance technology that allows manufacturers to monitor machinery in real-time, i.e., you can find out about a machine problem before it becomes a bigger issue that affects overall production. This can significantly benefit many manufacturers, allowing you to stay ahead and avoid production downtime at all costs.

Helping you with supply chain disruptions, automation supports manufacturers in pivoting production lines faster as you can implement tracking and forecasting data that you can access in real-time. Having this level of data and information at your fingertips allows you to make the best and most informed decisions for the business. Take the guesswork out of production.

Improving quality and accuracy, automation helps to eliminate human error, reduce accidents, and provide a high level of quality assurance and quality control so that production output is consistent.

Automation is a significant factor in supporting businesses in their sustainability drive and target of net zero by 2050, as automation looks to significantly reduce energy consumption and the overall level of waste manufacturers see on the production line.

Overcoming manufacturing bottlenecks with Innomech

At Innomech, we believe that automation should lead to process improvements. The focus should be on designing and developing purpose-built automation machinery that is bespoke to your business.

Using the evolvement of automation to improve productivity, reduce bottlenecks, boost profitability, and manage and meet ongoing compliance regulations – automation should be embraced and provide manufacturers with a feeling of empowerment.

At Innomech, our expert consultants support manufacturers throughout the UK with automation machine integration and the design and build of bespoke automated solutions to reduce product costs and improve output quality.

If you’re looking at innovative ways to reduce bottlenecks and futureproof your manufacturing processes going forward, book a call with our team today and see how we can help you.